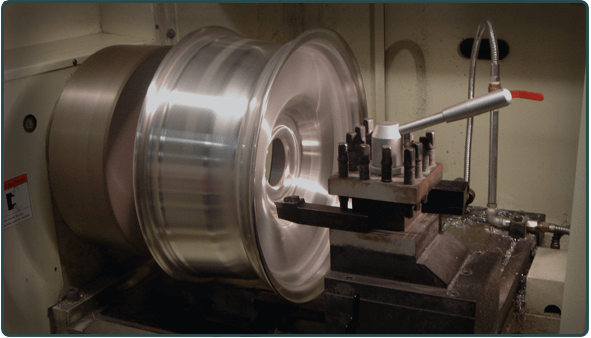

Many of our fixed shops are set up to offer CNC machining on a state-of-the-art CNC wheel lathe. This device is completely computerized and cuts a fine layer of aluminum from the entire face of the rim with exacting precision, producing a perfect finish equal to or better than original factory finishes.

Original equipment manufacturers are increasingly putting machined rims on their new vehicles. A machined faced wheel has a bright finish much like polished aluminum. However, upon closer inspection, machined rims have tiny circular machine lines cut into the aluminum. The only way to properly repair a machined wheel is with a CNC lathe. Some wheel repair providers offer a cheap coverup technique when it comes to machined wheels. That is never done at Kwicksilver.